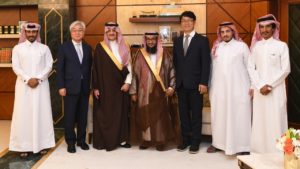

It was a great honor to meet with HRH Prince Saud Bin Nayef Bin Abdulaziz (Governor of the Eastern Province of the Kingdom of Saudi Arabia) in his office. It was an effective meeting in the presence of our business partners from South Korea. Mr. Salem Saeed gave a Commemorative Shield to the HRH Prince Saudi Bin Nayef on this great occasion.

Mr. Salem (CEO, GCTC) presented Commemorative Shields to Mr. Seong Tae Kim (Director & CEO of KST Plant Co. South Korea) & to Mr. Edward Soo Park (International Business Development Director) upon their visit and agreeing on establishing a JV Venture to localize KST technologies in the Kingdom of Saudi Arabia.

Mr. Salem (CEO, GCTC) presented Commemorative Shields to Mr. Seong Tae Kim (Director & CEO of KST Plant Co. South Korea) & to Mr. Edward Soo Park (International Business Development Director) upon their visit and agreeing on establishing a JV Venture to localize KST technologies in the Kingdom of Saudi Arabia.

It was nice & productive meeting with Eng. Baker Hammad in GCTC office. Later on, Mr. Salem Saeed Al Marri (CEO, Gulf Corners for Trading & General Contracting) invited Eng. Baker Hammad to the Dinner. Some officials from GCTC also participated in this Dinner hosted by Mr. Salem.

It was nice & productive meeting with Eng. Baker Hammad in GCTC office. Later on, Mr. Salem Saeed Al Marri (CEO, Gulf Corners for Trading & General Contracting) invited Eng. Baker Hammad to the Dinner. Some officials from GCTC also participated in this Dinner hosted by Mr. Salem.

GULF CORNERS FOR TRADING AND GENERAL CONTRACTING (GCTC) is searching for its strategic partners in India. Mr. Salem Saeed Al Marri, CEO of the company visited India from 18th of November to 23rd of November 2019. He visited following companies for collaboration and to formed agreements to handle projects collectively.

GULF CORNERS FOR TRADING AND GENERAL CONTRACTING (GCTC) is searching for its strategic partners in India. Mr. Salem Saeed Al Marri, CEO of the company visited India from 18th of November to 23rd of November 2019. He visited following companies for collaboration and to formed agreements to handle projects collectively.

By the Grace of Allah, it is very memorable and happy moments for GCTC to receiving CERTIFICATE OF APPRECIATION from Shaybah Producing Department. GCTC have achieved another milestones towards its vision. Company not only completed the project with a good way but completed before time and it shows the abilities & capabilities of GCTC Management, Technical and Professional Team…

By the Grace of Allah, it is very memorable and happy moments for GCTC to receiving CERTIFICATE OF APPRECIATION from Shaybah Producing Department. GCTC have achieved another milestones towards its vision. Company not only completed the project with a good way but completed before time and it shows the abilities & capabilities of GCTC Management, Technical and Professional Team…

GCTC (Gulf Corners for Trading & General Contracting) is building its new big Camp consisting of Workshops, Offices, Employees residence on a big area of 50,000 m2 as per Saudi Aramco Standards.

GCTC (Gulf Corners for Trading & General Contracting) is building its new big Camp consisting of Workshops, Offices, Employees residence on a big area of 50,000 m2 as per Saudi Aramco Standards.